Universal taps GARANT Master Tap

The GARANT Master Tap family for high process reliability and economic production

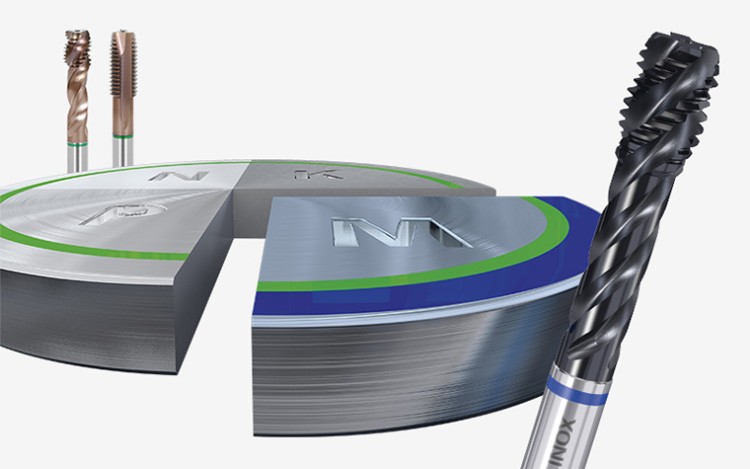

GARANT Master Tap – the all-round talent for machining threads. It combines highest process reliability with maximum universality. Be it steel, stainless steel, aluminium or cast iron – the special geometry ensures optimum chip formation. This universality reduces your tool diversity and at the same time improves your efficiency.

The new GARANT Master Tap STEEL HT has been specially developed for difficult-to-machine steels and materials with high tensile strength.

The newly developed GARANT Master Tap INOX is a specialist for VA stainless steels. It offers absolute process reliability and cost-effectiveness for machining this particularly challenging material.

Get to know the GARANT Master Tap family:

GARANT Master Tap STEEL HT – the problem solver for high-strength steels

The GARANT Master Tap STEEL HT impresses through its optimised coatings, which have been specially adapted to the various requirements for machining blind holes and through holes. The latest generation of the HSS-E-PM substrate is characterised by high homogeneity in the structure, thus achieving maximum cutting edge stability and wear resistance.The specially designed spiral point on the through hole tap ensures stability duringthe tapping process, even at high cutting forces.The cylindrically offset guide thread on the blind hole tap counteracts the occurrence of chip jamming and ensures very high process reliability.

Advantages that convince:

- Maximum performance.

- Outstanding for high-strength steels.

- Process-reliability.

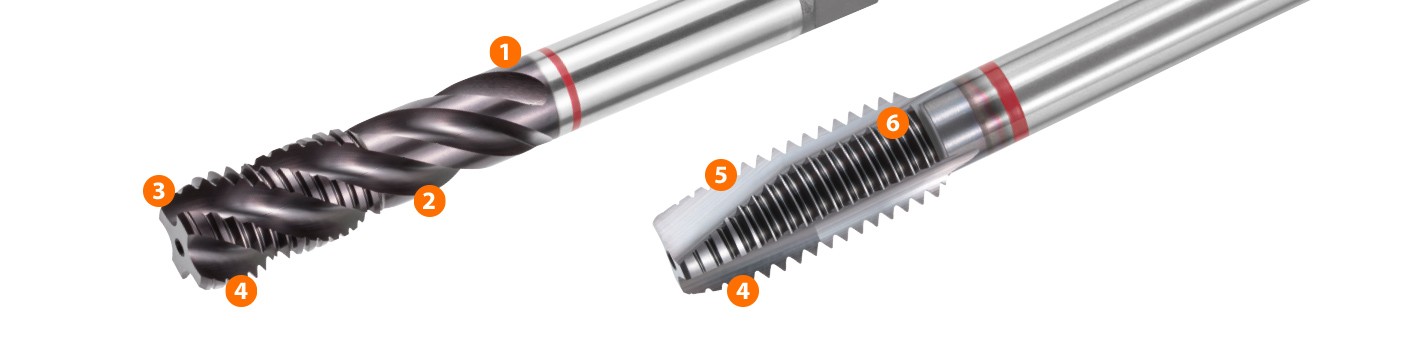

The outstanding features of the GARANT Master Tap STEEL HT:

- TiAlN coating: High heat resistance. Low frictional resistance.

- Optimized guide thread: High process reliability due to avoidance of chip jamming.

- Without interference contours: Threads can be tapped almost to thebottom of the hole.

- HSS-E-PM Substrate: High cutting edge stability and wear resistance.

- TiCN coating: Very smooth coating surface. Reduction of cutting resistance in the push direction.

- Special spiral point: High stability.

GARANT Master Tap INOX – the specialist for stainless steels

The new GARANT Master Tap INOX has been specially developed for machining stainless steels. It offers abolute process reliability in particularly challenging VA stainless steels. The optimum wear resistance of the tool material HSS-E-PM, its innovative micro-geometry and the low-friction TiAlN multi-layer anti-friction layer ensure the best possible process reliability and performance.

Advantages:

- TOP chip formation due to optimised cutting edges.

- TOP chip evacuation due to the special flute geometry.

- TOP wear resistance due to high-quality HSS-E-PM tool material.

- TOP efficiency due to the special micro-geometry.

- TOP tool life due to the most modern TiAlN multilayer coating.

Discover the outstanding characteristics of the GARANT Master Tap INOX:

- Optimised flute geometry: Controlled chip formation and chip evacuation.

- Special micro-geometry: Pitch-dependent parameters for the honed cutting edge.

- Design without interference contours: Threads can be tapped almost to the bottom of the hole.

- TiALN multilayer coating: Wear resistance due to the ultra-hard surface of the coating and reduced cutting temperatures due to reduced friction.

- HSS-E-PM tool material: High wear resistance and optimum rigidity.

- Optimised spiral point: Reduced cutting forces at the tap infeed.

- Stable geometry of the back of the tooth: Avoidance of cutting edge discontinuities when reversing.

GARANT Master Tap – the all-round talent

Our all-round talent GARANT Master Tap covers a broad range of tool materials. Due to the unique combination of high-quality tool material, innovative geometry and the latest coating technology the tap provides maximum performance in a variety of materials, whilst at the same time delivering absolute process reliability and efficiency.

Developed for very high performance in thread cutting:

- Optimised geometry of the back of the teeth: Ensures performance with high process reliability in a very wide range of materials. Cuts up the chips optimally and polishes the chip root.

- Specifically rounded-off cutting edges: For optimum chip formation from the first thread.

- Optimum chip evacuation due to special flute geometry.

- New cutting edge geometry: Permits use across a wide spectrum of materials.

- IInnovative AlTiX coating: For optimum wear behaviour. Reduces the cutting forces.

- Green ring: For general applications.

- High-quality tool material of HSS-E-PM. Homogeneous structure.

Properties GARANT Master Tap:

Chip formation:

1. A newly developed flute geometry ensures perfect chip formation and chip evacuation even under various cutting parameters:

Process reliability:

2. Competitors

3. GARANT Master Tap: Thread tapping to good process reliability without loose and twisted swarf. The particularly stable geometry of the back of the tooth ensures reliable cutting off at the chip root.

Universal geometry:

4. The optimised flute geometry and precisely matched honing of the cutting edges guarantee good process reliability even in cast iron.

Wear resistance:

5. Competitors: Cutting edge wear after 800 threads.

6. GARANT Master Tap: Cutting edge wear after 800 threads.

The HSS-E-PM tool material in conjunction with the new AlTiX high-performance coating provide impressively long tool life.

Precision:

7. Thanks to its special guide thread section the GARANT Master Tap achieves precise results even in ductile copper alloys and avoids any axial overcutting in the tapping process.

Surface:

8. Competitors

9. GARANT Master Tap: The smooth surface structure of the new high-performance coating permits high cutting speeds in wrought aluminium alloys. The reduced friction values avoid material adhesions and galling.

To the contact

To the contact