Face milling cutter GARANT TwinCut

Uniquely efficient with only one milling cutter for two types of milling insert

Roughing, finishing, profiting - High-performance milling cutter GARANT TwinCut TwinCut

Finishing and roughing with only one tool. Benefit from the advantages of the new GARANT TwinCut face milling cutter:

- One milling cutter for two types of insert – positioned via a shim.

- Double-sided insert for (1.) finishing and (2.) roughing operations.

- Very appealing cost/benefit ratio.

Face milling today

1. Finishing operations (primary application)

Milling insert characterised by:

Compensation of the cutting forces when entering into the material by the appropriate cutting edge design.

Insert ONEU 05T6, ONMU 05T6 double-sided 2 x 8 cutting edges.

Recommended:

Insert XNEU 05T6 Wiper – Fit a wiper edge insert to the carrier tool's highest cutting edge.

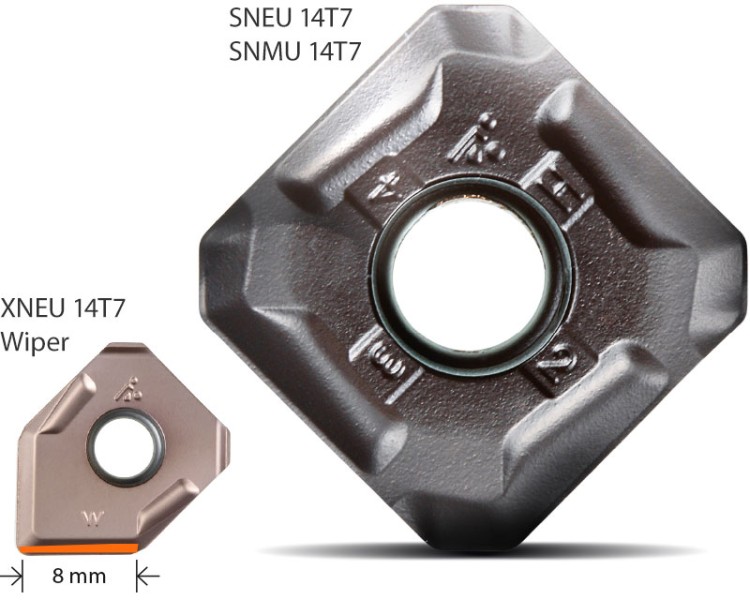

2. Roughing operations up to 6 mm depth of cut (primary application) and for finishing operations with wiper edge insert (secondary application)

Milling insert characterised by:

Markedly deep trough geometry at the cutting edge to evacuate large volume of chips. Inserts SNEU 14T7, SNMU 14T7 double-sided 2 x 4 cutting edges.

Optionally for finishing operations: XNEU 14T7 Wiper – Fit a wiper edge insert to the carrier tool's highest cutting edge.

(Do not mix different types of insert ON.U and SN.U!)

You can find the tool GARANT TwinCut and suitable indexable inserts in our online shop.

To the contact

To the contact